Mpo Trunk Cables

Low-Loss MPO-MPO Trunk Patch Cable

MPO trunk patch cable, a cost-effective

alternative to time-consuming field termination, is designed for high-density

fiber patching in data centers which need space saving and reduce cable

management troubles. MPO trunk type is for 40G QSFP+ SR4/CSR4, 100G QSFP28

SR4/PSM4, 400G SR8, SR4/LR4, optics direct connection and high-density data

center applications.

MPO cable is designed for high-density

application which offers excellent benefits in terms of installation time and

space saving. The cable assemblies are used in data centre, telecom, and

backbone application for 40-100G connectivity.

Optimizing Network Performance with MPO Trunk Cables

JTOPTICS® MPO trunk cables are pre-terminated, high-fiber-count cables that serve as the backbone for high-density, high-speed network infrastructures. In data centers, these cables simplify the deployment of 40G, 100G, 200G, and 400G Ethernet by enabling parallel optical connections between switches, patch panels, and servers. Their compact design reduces cable congestion and improves airflow.

Ensuring Excellence: MPO Cable Quality Testing

At JTOPTICS® we prioritize the highest standards in MPO cable quality testing to guarantee superior performance in high-density fiber optic networks. Our comprehensive testing procedures ensure that every MPO (Multi-fiber Push-On) cable meets rigorous performance criteria for optimal reliability and signal integrity.

Insertion Loss Testing

Ensures minimal signal loss for flawless data transmission.

Return Loss Testing:

Verifies low reflection for maximum signal efficiency.

Polarity Check:

Confirms correct fiber alignment for reliable connections.

Endface Inspection:

Inspects connector endfaces for cleanliness and precision.

Mechanical Durability:

Tests cable strength to withstand environmental and physical stress.

Insertion Loss Testing

Ensures minimal signal loss for flawless data transmission.

Return Loss Testing:

Verifies low reflection for maximum signal efficiency.

Polarity Check:

Confirms correct fiber alignment for reliable connections.

Endface Inspection:

Inspects connector endfaces for cleanliness and precision.

Mechanical Durability:

Tests cable strength to withstand environmental and physical stress.

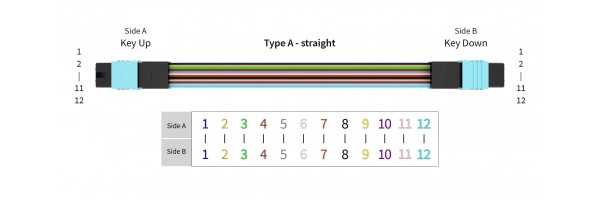

Polarity Type-A

The Left (Key Up) side is connected to the Right (Key Down) side. Fiber #1 attached to position 1 on both sides. Same applies for Fibers #2, #3, …, #12.

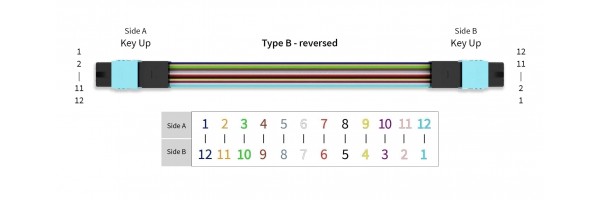

Polarity Type-B

The Left (Key Up) side is connected to the Right (Key Up) side. Fiber #1 attached to position 1 on the left and position 12 on the right. This can be written as Fiber #1 1-12. Same applies for Fibers #2 2-11, #3 3-10, …, #12 12-1.

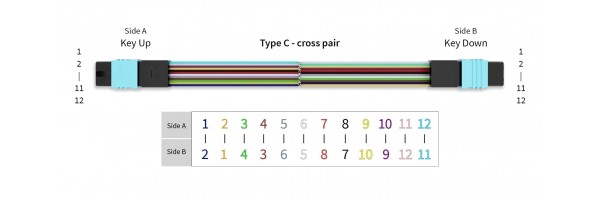

Polarity Type-C

The Left (Key Up) side is connected to the Right (Key Down) side. Fiber #1 attached to position 1 on the left and position 2 on the right. Fiber #2 attached to position 2 on the left and position 1 on the right. This can be written as Fiber #1 1-2, Fiber #2 2-1. Same applies for Fibers #3 3-4, #4 4-3, …, #12 12-11.